The logistics business is facing big challenges in the operational process of storing, transporting, and distributing goods; and willingness to take risk, there are many methods that streamline the workflow, ranging from the deployment of techniques for the security of the store or warehouse, to the use of various types of pallets to protect the product.

The latter becomes a factor, because the employment of a holder that is adapted to the characteristics of the goods and allow for correct stacking, reduces the risk of falling on rework and cost overruns.

In soliplast we have shown how the choice of the pallet indicated improvement, inventory management, response times, quality assurance and the management of profitability.

- Menu item

- What is a pallet in logistics?

- How many types of pallet are there?

- Pallet types according to their use

- Types of pallets according to your material

- What are the benefits of the injection of polymers?

- Why is it so important to use pallets and polyethylene for the industry?

- Types of pallets according to your measurements

- Pallet types according to the number of entries

- Pallet types according to their surface

- What is the best pallet according to the industry

- The cost of the pallets

- Where to get pallets

The logistics business is facing big challenges in the operational process of storing, transporting, and distributing goods; and willingness to take risk, there are many methods that streamline the workflow, ranging from the deployment of techniques for the security of the store or warehouse, to the use of various types of pallets to protect the product.

The latter becomes a factor, because the employment of a holder that is adapted to the characteristics of the goods and allow for correct stacking, reduces the risk of falling on rework and cost overruns.

In soliplast we have shown how the choice of the pallet indicated improvement, inventory management, response times, quality assurance and the management of profitability.

Contact

our advisor

Paola Flórez

- ventasinternacionales@soliplast.com.co

- +57 310 263 4629

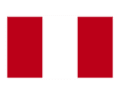

South america

What is a pallet in logistics?

A pallet, pallet, pallet, pallet or pallet is a platform or structure that serves as a base to have the goods evenly and enables your movement and storage, while optimizing the processes.

This structure can be made of different materials and with various designs to prevent damage to the objects they support and facilitate your transfer with forklift and/or transpalé or truck manual.

How many types of pallet are there?

We can find many kinds of pallets, determined by the characteristics, measures and international standards, all these talk about. However, the use for which it was designed, is what should drive the choice of the best pallet depending on the product that you are going to handle.

Pallet types according to their use

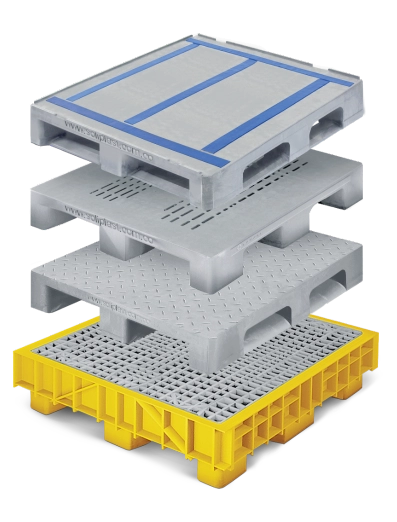

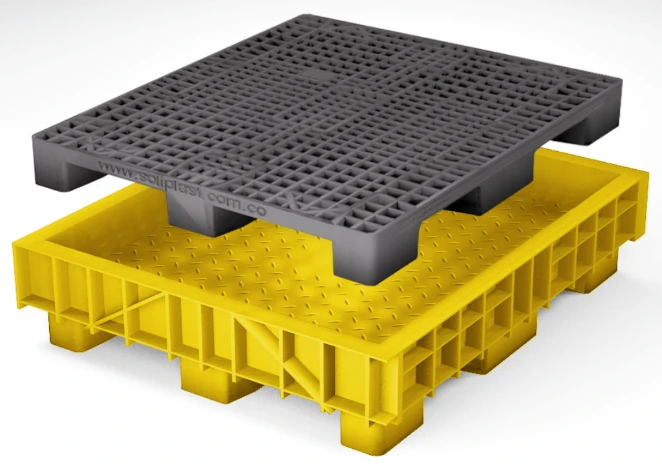

Pallets No Spill

This pallet has a body double that allow you to hold liquids in the background, avoiding to touch the floor and produce pollution, debris, or accidents. These liquids can be the product as such or waste of this.

What types of products should be transported in pallets non-spill?

Make a proper use and handling of certain substances considered as dangerous or harmful to human health, such as corrosive elements or other inputs other flammable, has become a topic of great importance in the industrial sector.

This is due to provide security for the system of employees in Bolivia, especially to the interior of the companies, and being able to act certain national rules in force, it has become a premise of corporate social responsibility.

It is for this reason that we have classified what products should be transported in pallets non-spill. Subjects who, due to their composition, physical-chemical, must be transported and/or stored, in pallets plastic non-spill, with some specific characteristics.

Elements explosives

There are different types of explosive products such as nitrogen, rockets, dynamite, and gunpowder, fireworks, and the devices or elements that trigger that must be handled with pallets non-spill, that allow for the successful containment of these hazardous materials.

Gaseous compounds

These types of items should be stored in a consistency liquefied or compressed or cooled. They can be classified, depending on their level of danger, such as:

- Suffocating

- Oxidising

- Flammable

- Toxic

Flammable liquids

In this type of dangerous elements you can find different flammable liquids such as alcohols, solvents, paint, gasoline, and esters.

Items flammable solids

This type of materials may have some type of reaction in spontaneous combustion or expel flammable gases that may come into contact, representing a danger, with items such as:

- Water

- Friction

- Coal

- Potassium

- Barium

- Sodium

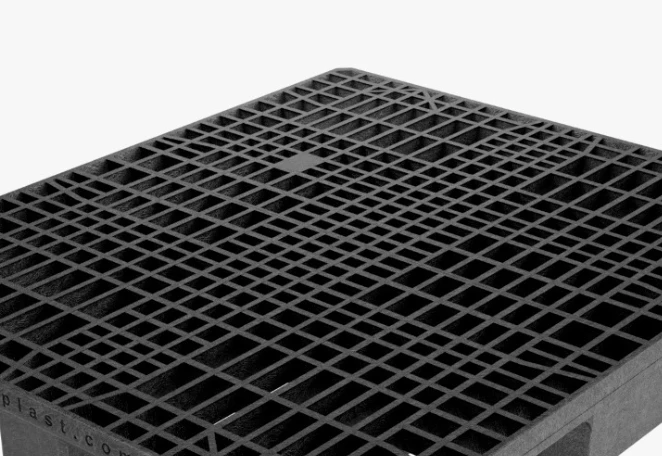

Pallet storage shelf

These pallets can withstand pressure or load for a long period of time in different types of racks, such as Drive-in or update Rollup, Selective and Dynamic; in addition, they can be exposed to low and high temperatures from -40 to 70 degrees celsius and can withstand a load of 8,000 kg (80-q) in floor and 1,400 kg (14 q) in a rack.

What types of products can be compact in pallet shelving?

The pallets shelving Soliplast are designed so that, according to the type of rack (Rack Selective Rack, Drive in Rack Dynamic) you can make the most efficient use of its load capacity and storage.

In them you can store products such as:

- Goods for industry

- Medical supplies, well packed

- Material plastic

- Inputs to the fashion industry, and much more

These are just some of the examples of the different types of products that you can distribute in the pallets to floor shelf Soliplast.

Its high strength makes this palette does not represent any risk for the operation and optimizes the handling of cargo.

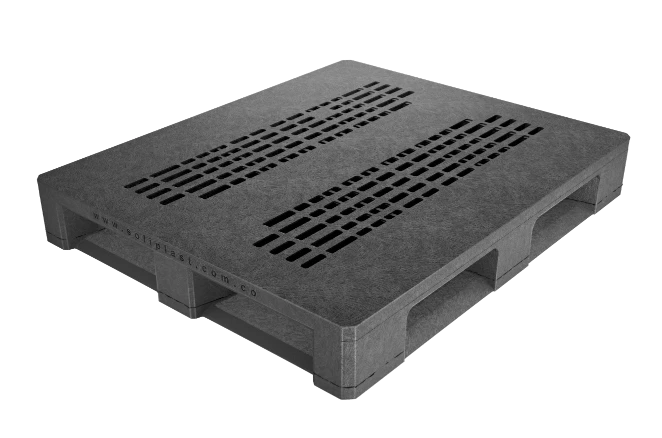

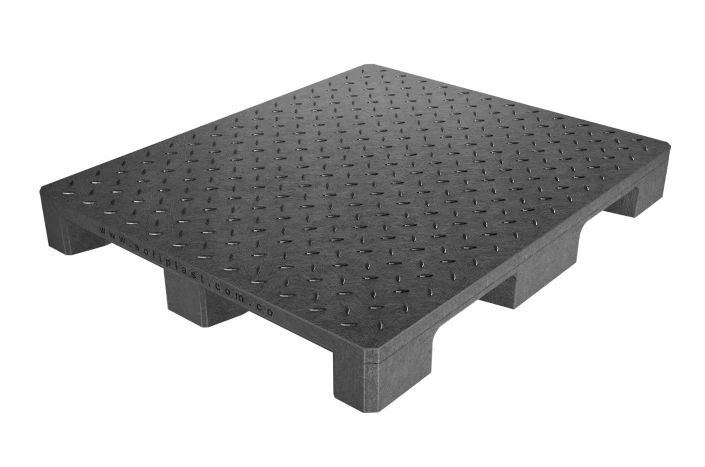

Pallet floor

Its design allows it to withstand a weight on dynamic loads from 1000 kg (10q) and 4,000 kg (40q) in static. This is the suitable for transport with montacarga, because it has entrances on all four sides.

Inside pallets for the floor there are some other sub-categories that further adjust the details of each product, some of these allow you to store in arrume black and/or house of cards.

What types of products can be stored on pallets for a floor?

The pallets plastic Soliplast are designed to achieve a charging stand much more weight on the floor. What makes the allied perfect for transporting in vehicles montacarga.

This is thanks to which they can be manipulated from its four sides. Some designs of our company offer the possibility of storing in arrume black or house of cards.

These pallets plastic allow you to store products such as:

- Baskets

- Bags

- Wood

- Sheet metal

- Porcelain

- Ceramic

- Cardboard industrial

- Chemical inputs

- Food and much more

Pallets for export

Also known as One Way or pallets packing or packaging; they have been designed to comply with the international standards, and for the optimization of processes; for this reason, although they have a lower resistance to the previous pallets plastics, can be made much lighter, and it is recommended that, when mobilized, the load is enzunchada or narrowed.

After seeing all of these specifications, the question that arises is: what is the material that has the versatility to achieve this offer? The truth is that you can do pallets with a variety of materials, but the current trend is to use pallets plastics.

This positioning should be, precisely, to the resistance, hygiene and savings they represent.

What types of products can be stored on pallets for export?

The pallets plastic Soliplast, type export, are items that are designed with special characteristics, which will provide a design conducive to ensure the smooth transport of goods through international routes.

Among the many products that can be transported through pallets for export, we can mention some such as:

- Lumps or bags of coffee

- Grains packed

- Boxes arrumadas

- Toys

- Clothing

- Dangerous items and much more

Types of pallets according to your material

Wooden Pallets

Are the most widely used in the logistics industry around the world, this is due to your great advantage: the price. However, it has several points against that are discourage its use, as its negative impact on the environment by cutting down trees and the difficulty that represents your maintenance: cleaning and fumigation.

In addition, this pallet has major disadvantages in the export, because in the country of destination are subject to phytosanitary inspection, which adds time to the process and if the wood pallets have any sign of fungal or pest, it opens up the possibility of a quarantine for the goods. This additional time, it is a cost overrun of fewer and fewer companies are willing to take.

Among other things, the regulation of wood packaging ISPM 15 established by the United Nations Organization for Food and Agriculture, is fixed in the process of preparing the pallet and its treatment, to deliver to the pallets certificates a tag or label control that identifies them. In case of non-compliance with the requirements imposed penalties on the offenders, these measures may end in the destruction of the goods for health risk.

However, these pallets plastics continue to have strength in the market because they have a good cycle life and resistance.

Pallet of Plastic

The requirements in force in the international market, the increase of freight rates and the lack of current availability of other alternatives has become this option in one of the more viable.

Contrary to the wood, to the disadvantage of the pallets, plastic may be the price, but this is just an appreciation surface, because long-term, the durability of this material may make this choice in a significant savings for companies.

On the other hand, their characteristics have also become attractive because their process of disinfection and cleaning is much more agile and do not require maintenance for repair, because his manner of manufacture is by injection, and gives as a result a single piece.

Contrary to what you may believe this alternative is much more friendly to the environment, because those pallets that have completed their useful life can be used as a feedstock for the production of some new or other products.

One of the initial doubt to which users can address this type of material is that they tend to warp, but these have been shown to withstand very well the pressure of the weight.

In addition, these pallets are also resistant to temperatures below – 40 °C and + 70°C.

Pallets Wood plastic

The polymer of natural origin mixed with plastic is a material that is a little unconventional, because, despite being a substitute ecological wood -an advantage-requires to be joined with brads and screws, such as the traditional wood, which means that you must have some kind of maintenance. In addition, its metal parts, can be a source of generation of bacteria. Within its advantages is the price, lower the pallet made completely in plastic.

Pallets of Metal

The long shelf life of these pallets and its stiffness are very attractive for certain industries, but its materials (steel or aluminum) makes them much heavier than the other options.

In addition, if we compare the 1,500 kg (15q) in motion and 4,000 kg (40q) in static load that can support a pallet of metal, it is evident that emerging materials such as plastic, represent a more economical choice, because they provide the same resistance without increasing the cost of transportation for their individual weight without load.

Pallet of Cardboard

The weight and resistance of this type of pallets that cannot be compared with the previous, because it has different uses, it is much more lightweight and easy to handle, so the load should be much lighter.

Its price is clearly lower than other alternatives, but its shelf life is shorter in length, can be damaged very easily.

The only thing that is left to say in front of the materials used for the production of pallets, is that currently there is not a material that combines best resistance, waterproofing and weight as the plastic. Remember that all types of pallets-according to the functions -which we saw in the first part is plastic and this shows his versatility.

Conoce nuestros pallets plásticos

Los pallets plásticos facilitan el movimiento y la carga de productos en camiones y contenedores, lo que ayuda a reducir el tiempo y el costo de transporte. Sin embargo, es importante que las empresas tomen en cuenta la calidad de las estibas que utilizan, ya que estibas mal construidas o de baja calidad pueden causar daños a los productos y a la maquinaria, y aumentar el riesgo de accidentes.

Tenemos pallets diseñados para diferentes funciones:

Pallet storage shelf

Una opción ideal para optimizar el espacio en almacenes y bodegas, permitiendo el apilamiento seguro y ordenado de productos en estanterías.

Pallets para almacenamiento en piso

Los pallets para almacenamiento en piso se utilizan cuando no se dispone de estanterías, ya que permiten el apilamiento directamente en el suelo.

Piso plásticos modulares

Los pisos plásticos modulares son una alternativa resistente y duradera a los pisos convencionales, ideales para áreas de alto tráfico y exposición a líquidos.

Pallets One Way tipo exportación

Los pallets One Way tipo exportación se utilizan para envíos internacionales, ya que son ligeras y resistentes, y no requieren ser devueltas después del uso.

Pallets antiderrame

Son ideales para el manejo de sustancias líquidas o peligrosas, ya que cuentan con una superficie antideslizante y un borde elevado para evitar derrames.

What are the benefits of the injection of polymers?

The pallets plastics, developed through a process of injection of polymer, they feature a cutting-edge technology known as foamed structural or Structural Foam.

This manufacturing process gives you, the final product a few thick walls and solid with a low weight, thanks to the mixture of HDPE with Nitrogen, which allows the pallet to be robust and therefore has a better performance in different storage scenarios.

In this sense, accompanied by a correct handling of the equipment mobilization, the pallet will have a useful life longer.

This type of pallets plastic Soliplast are manufactured under the highest quality standards, with High Density Polyethylene raw material, which is spearheading the process of injection of polymers or foamed structural.

What are the benefits of the use of HDPE under injection of polymers in plastics?

Now that we talked about why it is important to use the technique of foaming structural in the manufacture of pallets plastics, it is necessary to understand what are the major advantages provided by the use of the same strategies storage or transportation of freight in an enterprise:

Elasticity

The use of HDPE, low-foaming structural, in the manufacture of pallets plastic, allows the product to have greater flexibility at the time of the storage or transportation of goods.

It is lighter in weight

The pallets plastic, designed under a model of polymer injection, are lighter than other manufactured with other materials. This will provide a lower overhead to the time of transportation or storage of goods.

Longer service life

Various pallets plastic Soliplast have a shelf life up to 5 years.

Lower investment in the medium and long term: since multiple pallets Soliplast have a shelf life up to 5 years, you will need to invest less on repurchase of pallets conventional.

Chemical resistance and physical

The specialized components of our pallets plastic Soliplast allow them to have a resistance to physical and chemical much higher.

Are recyclable

The pallets plastic Soliplast are recyclable.

High quality materials

HDPE, allows the pallets plastics manufacture in Soliplast meet with some characteristics of manufacturing suitable; to be colorless and in terms of colorimetry next to the opaque.

Now that you know more about what are the great benefits of the injection of polymers, we invite you to meet our different types of pallets plastic Soliplast.

Why is it so important to use pallets and polyethylene for the industry?

To begin talking about the importance of the use of the pallets polyethylene in the industrial market, it is necessary to discuss his most notable benefit, and this is no more than the savings are so significant in terms of spending on conventional pallets that a company should do to maintain a stock of tools, which, in turn, allows you to perform, successfully, all its operations of loading, unloading, storage, transport and distribution of goods.

However, it is not the only advantage that would have a company to run its operations, by means of pallets polyethylene.

Some of the most important qualities of polyethylene implemented in pallets plastics, are:

- Resistance

- Safety

- Durability

- Longer service life

- Ease of cleaning

- Advantages transportation regulations

- Light weight

Then the polyethylene, precisely the one used in Soliplast (HDPE) or Polyethylene High Density, it is one of the most resistant on the market, so that their properties become accurate for all kinds of logistics solutions for businesses that use them.

Therefore, we want to know what the benefits are more relevant to use pallets polyethylene in your company. Please take note ✍!

| Benefits of using pallets polyethylene in your company | |

| They are much lighter | One of its most prominent advantage is the consistency of a weight much lighter than pallets conventional wood on the market. |

| Impermeability | Factors such as the water and other liquids are items that do not affect the durability, strength and consistency of the pallet polyethylene. These retain their original characteristics. |

| Increased strength and durability | The pallet polyethylene, or pallets, plastic Soliplast have a better resistance than wood; for these, with the passage of time and the conditions of saved, go spoiling, minimizing their life, durability and physical composition. |

| Safety | The pallets of polyethylene are waterproof, so they will not arrive on the inner bacteria that may affect the chemical and physical composition of the products. |

| Friendly with the environment | Our types of plastic packaging Soliplast are manufactured with recycled materials, allowing that, at the end of their useful life, they are also recyclable at 100%. |

| Easy to clean | Have you ever cleaned a pallet conventional? If so, then you already know how annoying it is that process, if you do not have the necessary tools and knowledge. Clean up a pallet of polyethylene Soliplast is very easy. |

| Customization | In Soliplast do pallet of polyethylene under strict standards of quality; in addition, we can also manufacture your products with the logos of your company, so you'll give your seal of quality, and will show your allies the importance that you give to your work of logistics distribution and storage responsible. |

Types of pallets according to your measurements

Continuing with the theme of the international standards, for these are the dimensions of a pallet are also important. The most recognized in the world are the pallet american and the europallet that we will see in more detail below.

Pallet american

Also known as isopallet, pallet or industrial pallet universal.

- Characteristics established by the ISO 3676.

- Their measures are standard 1200 x 1000 mm

- A pallet american weighs approximately 25 Kg or 0.25 q.

- Supports a load of a maximum of 1200 kg or 12 q.

- The countries that use them are the united States and Japan.

Pallets europe

World renowned as europaleta or europalé.

- Its features are approved by the EPA, the European Association of Pallets.

- The standard measure of a europalet is of 1200 x 800 mm

- A pallet the european weighs regularly to 27 Kg, or 0.27 qs.

- Withstand a static load of 4,000 kg (40 q) and 1,400 kg (14 q) in motion.

- They are the most used throughout the old continent.

The main difference between a pallet american and a europalet

- The main difference is their size, and this has a practical reason, the pallets are europeans more small to achieve a better location and use of space in the interior of the carriages of the trains in europe.

- Americans have a larger space for the distribution of the load and the europeans will support more weight.

We must make it clear that there are other measures available on the market, as of 1165×1165 mm, 1100×1100 mm, 1067×1067 mm and 1016 x 1219 mm, but these are not frequently used.

Pallet types according to the number of entries

This aspect is related to the movement of cargo, the number of entries limited form of transport.

- Pallets with two entries: has two sides closed, and only two open, which makes it difficult to access them with the montacarga, however, these are ideal for racks selective due to its structure.

- Pallets with four entries: the four sides have openings, which means that these have a higher mobility because they can be attached from any side.

Pallet types according to their surface

As well as the number of entries is determined by a process, there are pales that according to their surface represent an advantage as:

- Pallet with tabs: having a set of wings or tabs that protrude from the structure extends the surface on which you can cubicar the load. In addition, the tabs work as a brake for the jabas plastic.

- Pallet reversible or double-sided: they have two faces are identical and both have the same functions and load capacity.

- Pallets with surfaces completely closed: these feature a small relief in alfajor that makes the times of anti-slip.

- Pallet with surface ventilation discrete or maximum: they are ideal for when the products are in cold rooms and/or frozen, because it allows the air circulation through them.

Contact

our advisor

Paola Flórez

- ventasinternacionales@soliplast.com.co

- +57 310 263 4629

South america

What is the best pallet according to the industry

The logistical needs specific to your company are the ones that will determine what is the better pallet, however,I present to you the most used by the sectors of the primary and secondary of the economy.

Food industry and agro

Difficulties in the use of wooden pallets

- Lack of safety for metal parts that will rust and put you at risk of contamination of the products.

- Break at low temperatures.

- The moving and lifting of the jabas rack is a risk factor for the operation and health of the employees.

- The pallets of wood require fumigation to meet the standard ISPM 15.

Solutions that bring the pallets plastic Soliplast

- Pallets monolithic, without the use of nails or staples that pose a risk of contamination. The pallet is injected as a single piece, no parts the a, so there is no risk of contamination. In addition, they do not have chips that are a risk to workers.

- Help the company comply with the standard HACCP-ISO 22000 Standard: the Guarantee of food safety.

- These pallets are special to camera freeze. You can develop special formulations according to the operation of each company.

- Odorless and non-toxic, the material is suitable for contact with food, it is also easy to wash and disinfect.

- Tab edge optional special for jabas or (common operations of agri-food), in order to make more secure operations.

- Does not require fumigation which facilitates phytosanitary inspections.

Pharmaceutical industry

Needs of the industry

- Safety, for the pharmaceutical industry, it is imperative that the environments are free of particles, as any fragment, however small, can contaminate the drugs.

Solutions that bring the pallets plastic Soliplast

- Our pallets do not give off dust or are carriers of fungi, or insects.

- Odorless, non-toxic and easy to wash, clean and disinfect

- Pallet light that provide improvements in the logistics processes and provide improvements in the logistics processes and ensure the quality of the products in the long term.

Beverage and dairy industry

Needs of the industry

- The pallets are strong to use on the rack and floor, to improve the efficiency in the processes.

- Pallets that are suited to the different products, types of packaging and bottling. This is not the case with wood.

- It requires a pallet that can be rotated between the different processes, plants and distributors, for this wood material is the most indicated.

Solutions that bring the pallets plastic Soliplast

- Broad portfolio designed for different load capacities and use. Technology of foamed structural offered pallets are sturdy, resistant and at the same time lightweight for easy handling on the part of the staff.

- Pallets that do not require maintenance, saving time and costs.

- Pallets are easy to wash and suitable for the weather.

- Pallets with non-slip surface and tab edge special for the use of jabas plastic (where is stored the milk in the bag for distribution).

- Option of customization of pallets with colors and/or logo on screen or embossed to the identification of the same during the transfer between operations.

Chemical Industry

Difficulties and needs of the industry

- Risk of spills in the operations.

- Pallets are manufactured in materials that are not compatible with certain chemicals

- To comply with the System of Safety and Health (OSH).

Solutions that bring the pallets plastic non-spill Soliplast

- Compatibility with +150 different chemical aggressive and corrosive

- Manufacturing versatile: containment capacities from 35 to 1000 liters.

Can be stored 1,2,3 or 4 barrels / cylinders pallet or IBC 1000 liters. - Complies with the regulations of harmful substances.

- Special models available for use in rack and floor. Can be mobilized with forklift truck or pallet jack.

- Feature drainage system for easy cleaning.

- Avoids risks to the workers come in contact with chemicals, liquids, and/or oils. (if you stay on the floor can slide).

Still don't know which is the best

pallet for your business?

We have created a content to help you choose, in it you can find uses for different kinds of pallets according to its material, functions or measures, and recommendations to solve the needs related to pallets for the transportation and storage of products of some industries. This information will surely be very useful for you, read us!

This information will certainly be useful to you. ¡Léenos!

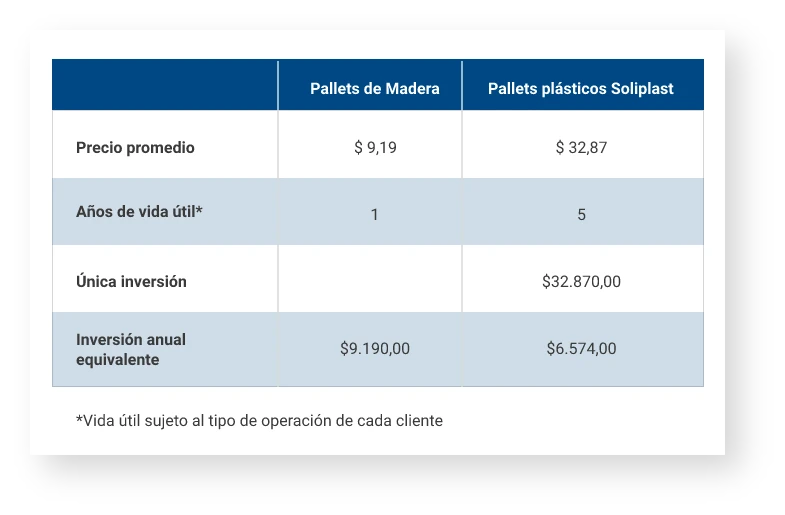

The cost of the pallets

As we have already mentioned, the material is where there is the greatest difference in the prices. With the intention of making a more in-depth analysis only talk about the two that have more strength in the market: the pallet of plastic and wood.

Comparison of prices and benefits

Calculation is carried out with the reference of pallet of floor ER-100S-4E-V1, and under a basis of purchase of 1,000 units.

Where to get pallets

Our factory pallet is found in Colombia, however, we have made submissions to The Peace and other cities of Bolivia without generating extra costs of transport. You can validate with our advisor minimum amounts of shipping.

Sell-pallets or pallets in cities such as La Paz, Cochabamba, Santa Cruz de la Sierra, Oruro, Potosí, among other areas of the country. In addition, we also have available here our rater of pallets:

We have several channels of attention in Bolivia to all of our customers. Know here what they are and talk with our consultants commercial:

Contact

our advisor

Paola Flórez

- ventasinternacionales@soliplast.com.co

- +57 310 263 4629

South america